Kathwada, Ahmedabad, Gujarat

- GST NO. : 24BAKPP1655H1ZM

Vacuum Packaging Machine

Leading Manufacturers, Exporters, Wholesaler and Retailer of Almond Vacuum Packaging Machine, Atta Vacuum Packing Machine, Automatic Flat Type Rice Vacuum Packing Machine, Automatic Thermoforming Vacuum Packaging Machine, Automatic Vacuum Packaging Machine, Belt Type Vacuum Packaging Machine, Brick Type Vacuum Packing Machine, Cheese Vacuum Packing Machine, Double Chamber Fish Vacuum Packaging Machine, Double Chamber Vacuum Packaging Machine, Dry Fish Vacuum Packing Machine, Fish Vacuum Packaging Machine, Flour Vacuum Packing Machine, Heavy Duty Vertical Chamber Vacuum Packing Machine, Horizontal Pouch Vacuum Packaging Machine, Khakhra Vacuum Packaging Machine, Meat Vacuum Packaging Machine, Nozzle Type Chamberless Vacuum Packaging Machine, Paneer Tray Thermoforming Vacuum Packaging Machine, Pulses Vacuum Packing Machine, Semi Automatic Chamberless Vacuum Packing Machine and Semi Automatic Single Chamber Vacuum Packaging Machine from Ahmedabad.

| Business Type | Manufacturer, Exporter, Supplier |

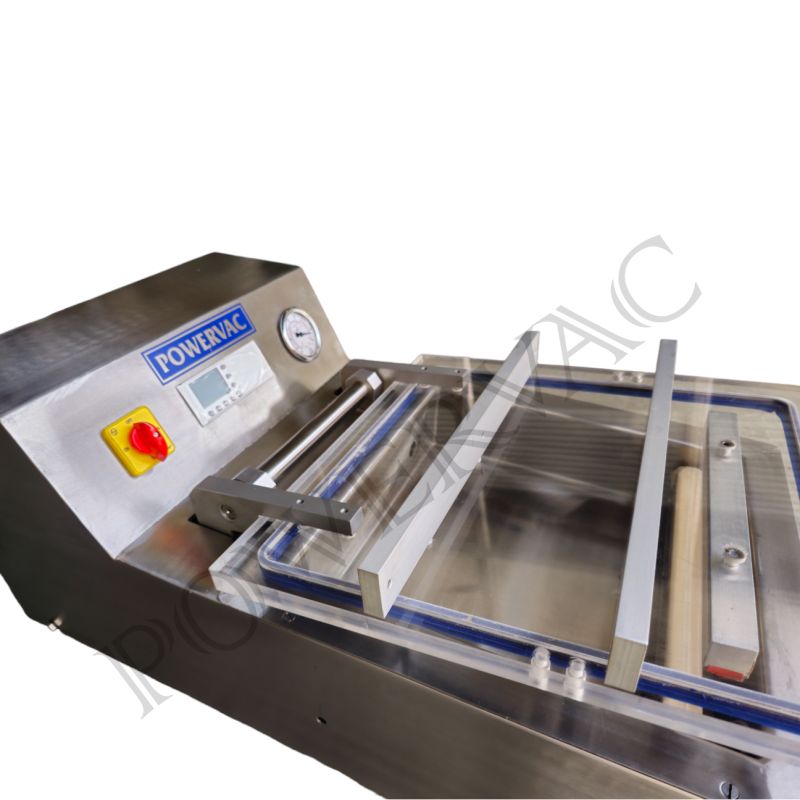

| Brand Name | Powervac |

| Material | Stainless Steel |

| Driven Type | Electric |

| Condition | New |

| Automatic Grade | Automatic,Manual |

| Certification | ISO 9001:2008 |

| Voltage | 230 Volts,50 Hz. I Phase/ III Phase - As Per Client |

| Packaging Type | Pouch |

| Model No. | SCH-650 |

| Type | Vacuum Packaging Machine |

| Function | Sealing, Packing |

| Country of Origin | India |

| Sealing Length | 620mm |

| Chamber Type | Single |

| Chamber Size | 500mm |

| Bag Volume | Upto 5 Kgs |

| Dimension | 1050(L) x 750(W) x 960(H)mm |

| Product Code | SCH-650 |

| Payment Terms | L/C, T/T, Western Union, Other |

| Delivery Time | 3 to 4 weeks |

Preferred Buyer From

| Location | Worldwide |

Our table top vacuum packing machine is a compact and convenient appliance used to remove air from packaging, such as bags or containers, in order to extend the shelf life of food and other perishable items. By removing air from the packaging, it helps prevent the growth of bacteria and molds, keeping the contents fresher for a longer period.

Key features of our table top vacuum packing machine typically include:

1. Vacuum sealing: Our Machine has motorized vacuum pump from (busch -Germany) to suck the air out of the packaging, creating an airtight seal around the contents.

2. Seal settings: Our machine allows you to adjust the seal time and intensity, which can be useful when working with different types of packaging materials or products.

3. Control panel: Our table top vacuum sealer has a user-friendly control panel from MITSUBHISHI –Japan that allows you to adjust settings, start/stop the vacuum process, and monitor the sealing progress.

4. Seal bar: Our machine has a sealing strip or bar that creates the airtight seal on the packaging. The size of the seal bar determines the maximum width of the bag or container that can be sealed.

5. Bag cutter: Our models may include a built-in bag cutter, allowing you to customize the size of the bags to fit your products precisely.

6. Built-in roll storage: Our table top vacuum sealers have integrated storage for vacuum sealing rolls, making it convenient to have the packaging material readily available.

7. Compact size: Our Table top vacuum packing machines are designed to be space-saving and easy to use in smaller kitchens or limited countertop areas.

8. Versatility: While primarily used for food preservation, these machines can also be used to vacuum seal non-food items, such as important documents or clothing for travel.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Powervac |

| Material | Stainless Steel |

| Driven Type | Electric |

| Color | Silver |

| Condition | New |

| Automatic Grade | Semi Automatic |

| Certification | ISO 9001:2008 |

| Voltage | 230 Volts |

| Packaging Type | Pouch |

| Model No. | TT-300 |

| Type | Vacuum Packaging Machine |

| Weight (Kg) | 40 kg |

| Function | Sealing, Packing |

| Country of Origin | India |

| Sealing Length | 400mm |

| Chamber Type | Single |

| Product Code | TT-300 |

| Payment Terms | L/C, T/T, Western Union, Other |

| Delivery Time | 3-4 Weeks |

Preferred Buyer From

| Location | Worldwide |

Standard Features:

- Horizontal Table top showy design suitable for retail grocery shops, small dairy shops, super malls, etc.

- Transparent acrylic top to see packing process.

- Mitsubishi (Japan) Plc based control panel with 4-Line LCD Display, adjustable vacuum time, sealing time, etc.

- High speed vacuum pump (Busch Germany).

- Stainless steel body, no sharp edges, use cast aluminium & other nonferrous materials to safe rust issue and easy cleaning.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Powervac |

| Material | Stainless Steel |

| Driven Type | Electric |

| Color | Silver |

| Condition | New |

| Automatic Grade | Semi Automatic,Semi Automatic |

| Certification | ISO 9001:2008 |

| Voltage | 230 Volts |

| Packaging Type | Pouch |

| Model No. | TT-300 |

| Type | Vacuum Packaging Machine |

| Weight (Kg) | 40 kg |

| Function | Sealing, Packing |

| Country of Origin | India |

| Weight | 40 Kg |

| Machine dimensions (LxWxH) (mm) | 740(L) x 425(W) x 340(H)mm |

| Sealing Length | 400mm |

| Chamber Type | Single |

| Dimension | 740(L) x 425(W) x 340(H)mm |

| Product Code | TT-300 |

| Payment Terms | L/C, T/T, Western Union, Other |

| Delivery Time | 3 to 4 Weeks |

Preferred Buyer From

| Location | Worldwide |

Standard Features:

· Horizontal Table top showy design suitable for retail grocery shops, small dairy shops, super malls, etc.

· Transparent acrylic top to see packing process.

· Mitsubishi (Japan) Plc based control panel with 4-Line LCD Display, adjustable vacuum time, sealing time, etc.

· High speed vacuum pump (Busch Germany).

· Stainless steel body, no sharp edges, use cast aluminium & other nonferrous materials to safe rust issue and easy cleaning.

Technical Specifications:

Machine Model: TT-300

Distance Between Seal Bars: 290

Usable Chamber Height: 85

Seal Bar Length: 300

No. of Seal Bar: 1

Seal Width: 6

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Powervac |

| Material | LDPE |

| Driven Type | Electric |

| Condition | New |

| Automatic Grade | Automatic |

| Certification | ISO 9001:2008 |

| Voltage | 440V |

| Model No. | TMF-500 |

| Type | Vacuum Packaging Machine |

| Function | Sealing, Packing |

| Country of Origin | India |

| Capacity | 450 kg/hr |

| Packaging Products | Bakery, Confectionary |

| Max Forming Depth | 80-120 mm |

Preferred Buyer From

| Location | Worldwide |

We are Providing Vacuum Thermoforming Machine for Food Packaging.

A vacuum thermoforming machine, also known as a foam molding machine or foam expansion machine, is a type of industrial equipment used to produce foam products through a process known as thermoforming and foam expansion. Thermoforming involves heating a plastic sheet until it becomes pliable, then shaping it over a mold and cooling it to create a specific product shape. Foam expansion, on the other hand, involves injecting gas or air into a polymer melt to create a foam structure within the material.

Thermofoaming machines combine these processes to create foam products, often used in various industries such as packaging, automotive, construction, and more. The foam products can offer benefits such as light weighting, thermal insulation, and cushioning.

Here's a general overview of how a thermofoaming machine works:

1. Material Preparation: The machine starts by feeding plastic pellets (usually thermoplastic materials) into a hopper. These pellets are then melted down to form a polymer melt.

2. Molding: The melted polymer is extruded onto a mold or a set of molds. The molds are designed to give the desired shape to the final foam product.

3. Foam Expansion: During the molding process, a gas or air is introduced into the polymer melt. This can be achieved by various methods, such as chemical blowing agents or physical foaming techniques. As the gas expands, it creates a cellular foam structure within the material.

4. Cooling and Solidification: Once the foam has expanded and taken on the desired shape, the material is cooled rapidly to solidify the foam structure.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Powervac |

| Material | Stainless Steel |

| Driven Type | Electric |

| Condition | New |

| Automatic Grade | Automatic,Semi Automatic |

| Voltage | 430V |

| Packaging Type | Pouch |

| Model No. | ABV-1100 |

| Type | Vacuum Packaging Machine |

| Function | Sealing, Packing |

| Country of Origin | Made In India |

| Sealing Length | 400mm |

| Chamber Type | Single |

| Sealing Power | 750 W |

| Frequency | 50 Hz |

| Phase | 3 Phase |

| Product Code | ABV-1100 |

| Payment Terms | L/C, T/T, Western Union, Other |

| Delivery Time | 3 to 4 weeks |

Preferred Buyer From

| Location | Worldwide |

An automatic belt type vacuum packing machine is a type of packaging equipment that is used to vacuum-pack products. It is designed to efficiently and automatically package various items, such as food products, pharmaceuticals, electronics, and other goods, in airtight bags or pouches.

Here's how the automatic belt type vacuum packing machine typically works:

1. Loading: The operator places the products to be packed onto the conveyor belt of the machine. The conveyor belt moves the items into the packaging area.

2. Vacuum sealing: Once the product is inside the bag, the machine initiates the vacuum sealing process. It removes the air from the bag, creating a vacuum environment around the product. This helps to extend the shelf life of the packaged goods by reducing oxygen levels, inhibiting bacterial growth, and preventing oxidation.

3. Sealing: After the air has been removed, the machine seals the bag shut to maintain the vacuum. The sealing process can be achieved through heat sealing, where the bag edges are fused together using heat.

4. Conveyor movement: The conveyor belt continues to move, bringing the next product into position for packaging. The process repeats for each item on the belt.

Automatic belt type vacuum packing machines offer several advantages, including increased packaging speed, consistent sealing quality, and enhanced product presentation. They are often used in industries that require high-volume packaging operations or where vacuum packaging is necessary to preserve product quality and extend shelf life.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Powervac |

| Material | Stainless Steel |

| Driven Type | Electric |

| Color | Silver |

| Condition | New |

| Automatic Grade | Semi Automatic,Automatic |

| Power | 750 W |

| Certification | ISO 9001:2008 |

| Voltage | 430V |

| Packaging Type | Pouch |

| Model No. | ABV-1100 |

| Type | Vacuum Packaging Machine |

| Function | Sealing, Packing |

| Country of Origin | India |

| Seal length L2 (mm) | 400mm |

| Voltage / Frequency | 50 Hz |

| Sealing Length | 1000mm |

| Chamber Type | Single |

| Dimension | 1850x1900x1250 mm |

| Sealing Power | 750 W |

| Product Code | ABV-1100 |

| Payment Terms | L/C, T/T, Western Union, Other |

| Delivery Time | 3 to 4 Weeks |

Preferred Buyer From

| Location | Worldwide |

Here's how the automatic belt type vacuum packing machine typically works:

- Loading: The operator places the products to be packed onto the conveyor belt of the machine. The conveyor belt moves the items into the packaging area.

- Vacuum sealing: Once the product is inside the bag, the machine initiates the vacuum sealing process. It removes the air from the bag, creating a vacuum environment around the product. This helps to extend the shelf life of the packaged goods by reducing oxygen levels, inhibiting bacterial growth, and preventing oxidation.

- Sealing: After the air has been removed, the machine seals the bag shut to maintain the vacuum. The sealing process can be achieved through heat sealing, where the bag edges are fused together using heat.

- Conveyor movement: The conveyor belt continues to move, bringing the next product into position for packaging. The process repeats for each item on the belt.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Powervac |

| Material | Stainless Steel |

| Driven Type | Electric |

| Color | Silver |

| Condition | New |

| Automatic Grade | Semi Automatic,Semi Automatic |

| Power | 230 Volts, 50 Hz. I Phase |

| Certification | ISO 9001:2008 |

| Packaging Type | Pouch |

| Model No. | SCV-500 |

| Type | Vacuum Packaging Machine |

| Weight (Kg) | 250 KG |

| Function | Sealing, Packing |

| Country of Origin | India |

| Weight | 250 Kg |

| Chamber dimensions (L1xW1xH1) (mm) | 760(L) x 730(W) x 1300(H) mm |

| Seal length L2 (mm) | 500mm |

| Voltage / Frequency | 230 Volts, 50 Hz. I Phase |

| Sealing Length | 500mm |

| Chamber Type | Single |

| Chamber Size | 760(L) x 730(W) x 1300(H) mm |

| Bag Volume | Up to 10 Kg |

| Product Code | SCV-500 |

| Payment Terms | L/C, T/T, Western Union, Other |

| Delivery Time | 3 to 4 Weeks |

Preferred Buyer From

| Location | Worldwide |

A vertical type brick vacuum packing machine, is a packaging equipment used to package products in a brick-shaped format while removing air (vacuum) from the package.

Here's a breakdown of the key components and the working process of a typical vertical type brick vacuum packing machine:

1. Product Feeding: The machine is equipped with a feeding system that allows the product to be loaded into the packaging machine. The product can be in the form of granules, powders, liquids, or solid pieces, depending on the machine's capabilities.

2. Film Unwinding: The packaging material, usually a flexible film roll, is unwound and guided through the machine. The film can be made of various materials, such as plastic, aluminium, or laminates, depending on the product's requirements and the desired level of vacuum sealing.

3. Forming the Package: The film is formed into a tube by vertical sealing jaws. The sealing jaws create vertical seals on both sides of the film, forming a continuous tube to hold the product.

4. Product Filling: The product is dispensed into the formed tube of the packaging material.

5. Vacuum Sealing: Once the product is filled, the machine starts the vacuum sealing process. The open end of the tube is fed into a vacuum chamber, where the air is extracted, creating a vacuum inside the package. The vacuum helps to extend the product's shelf life by reducing oxygen levels, preventing spoilage, and maintaining product freshness.

6. Sealing and Cutting: After the vacuum is created, the machine seals the open end of the tube, creating a sealed brick-shaped package.

Vertical type brick vacuum packing machines are commonly used in the food industry for packaging products like coffee, snacks, cereals, frozen foods, and more. They offer efficient and hygienic packaging solutions with the added benefit of vacuum sealing to enhance product quality and shelf life.

| Business Type | Manufacturer, Exporter, Supplier |

| Sealing Length | 500mm |

| Chamber Type | Single |

| Automation Grade | Semi-Automatic |

| Chamber Size | 400mm |

| Weight | 250 Kg |

| Power | 230 Volts, 50 Hz. I Phase/ III Phase - as per client |

| Brand Name | Powervac |

Preferred Buyer From

| Location | Worldwide |

The vacuum packing process typically involves the following steps:

- Preparation: Ensure that the item or food you want to vacuum pack is clean and dry. This is important to prevent any moisture from affecting the sealing process or the product itself.

- Place the item in a vacuum bag: Put the item you want to package inside a specially designed vacuum bag. These bags are usually made of durable, airtight materials such as polyethylene or nylon. Make sure to leave enough space at the opening of the bag for sealing.

- Vacuum sealing: Place the open end of the bag into the vacuum sealer machine and close the lid. The machine will then remove the air from the bag, creating a vacuum. The exact process may vary depending on the type and model of the vacuum sealer you are using. Once the air is removed, the machine will automatically seal the bag.

- Inspection: After sealing, visually inspect the package to ensure that it is properly sealed and airtight. Check for any leaks or gaps in the seal.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Powervac |

| Driven Type | Electric |

| Condition | New |

| Automatic Grade | Automatic |

| Power | 1.75 KW |

| Certification | ISO 9001:2008 |

| Voltage | 430w |

| Packaging Type | Pouch |

| Model No. | DCH650/750/800 |

| Type | Double Chamber Vacuum Packaging Machine |

| Weight (Kg) | 550 KG |

| Country of Origin | Made In India |

| Pump | Busch - Germany |

| Seal length L2 (mm) | 500mm |

| Machine dimensions (LxWxH) (mm) | 1560*910*1050 |

| Voltage / Frequency | 430w |

| Sealing Length | 400mm, 620mm, 920mm |

| Chamber Type | Double |

| Automatic | 430V |

| Sealing Power | 500 W, 750 W |

| Product Code | DCH650/750/800 |

| Payment Terms | L/C, T/T, Western Union, Other |

| Delivery Time | 3 to 4 Weeks |

Preferred Buyer From

| Location | Worldwide |

Design suitable for upto 10 KG Pack with High Speed Vacuum Pump.

Heavy Duty One Piece Cast Aluminium Top.

Long lasting 6mm Heating Elements for Accurate Sealing Results.

Vacuum & Gas Control by Sensor for accurate level.

BUSCH(Germany) Vacuum Pump.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Powervac |

| Driven Type | Electric |

| Condition | New |

| Automatic Grade | Automatic,Automatic |

| Certification | ISO 9001:2008 |

| Voltage | 430V |

| Packaging Type | Bags, Pouch |

| Model No. | DVH 650 |

| Type | Double Chamber Vacuum Packaging Machine |

| Country of Origin | Made In India |

| Sealing Length | 400mm |

| Chamber Type | Double |

| Sealing Power | 500 W |

| Frequency | 50 Hz |

| Phase | 3 Phase |

| Material | Stainless Steel |

| Product Code | DVH 650 |

| Payment Terms | L/C, T/T, Western Union, Other |

| Delivery Time | 3 to 4 weeks |

Preferred Buyer From

| Location | Worldwide |

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Powervac |

| Material | Stainless Steel |

| Driven Type | Electric |

| Condition | New |

| Automatic Grade | Semi Automatic,Automatic |

| Certification | ISO 9001:2008 |

| Voltage | 430w |

| Packaging Type | Pouch |

| Model No. | DCH650/750/800 |

| Type | Vacuum Packaging Machine |

| Weight (Kg) | 550 KG |

| Function | Sealing, Packing |

| Country of Origin | India |

| Weight | 430V |

| Pump | Busch - Germany |

| Chamber dimensions (L1xW1xH1) (mm) | 1560*910*1050 |

| Sealing Length | 500mm |

| Chamber Type | Double |

| Sealing Power | 500 W |

| Frequency | 50 Hz |

| Product Code | DCH-650 |

| Payment Terms | L/C, T/T, Western Union, Other |

| Delivery Time | 3 to 4 Weeks |

Preferred Buyer From

| Location | Worldwide |

Product Description

Design suitable for upto 10 KG Pack with High Speed Vacuum Pump.

Heavy Duty One Piece Cast Aluminium Top.

Long lasting 6mm Heating Elements for Accurate Sealing Results.

Vacuum & Gas Control by Sensor for accurate level.

BUSCH(Germany) Vacuum Pump.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Powervac |

| Material | Stainless Steel |

| Driven Type | Electric |

| Condition | New |

| Automatic Grade | Automatic,Manual |

| Certification | ISO 9001:2008 |

| Voltage | 230V-1PH-50Hz |

| Packaging Type | Pouch |

| Model No. | SCH-650 |

| Type | Vacuum Packaging Machine |

| Function | Sealing, Packing |

| Country of Origin | India |

| Weight | 40 Kg |

| Sealing Length | 10 Inch |

| Chamber Type | Single |

| Dimension | 750 x 450 x 500 mm |

| Product Code | SCH-650 |

| Payment Terms | L/C, T/T, Western Union, Other |

| Delivery Time | 3 to 4 weeks |

Preferred Buyer From

| Location | Worldwide |

Our table top vacuum packing machine is a compact and convenient appliance used to remove air from packaging, such as bags or containers, in order to extend the shelf life of food and other perishable items. By removing air from the packaging, it helps prevent the growth of bacteria and molds, keeping the contents fresher for a longer period.

Key features of our table top vacuum packing machine typically include:

1. Vacuum sealing: Our Machine has motorized vacuum pump from (busch -Germany) to suck the air out of the packaging, creating an airtight seal around the contents.

2. Seal settings: Our machine allows you to adjust the seal time and intensity, which can be useful when working with different types of packaging materials or products.

3. Control panel: Our table top vacuum sealer has a user-friendly control panel from MITSUBHISHI –Japan that allows you to adjust settings, start/stop the vacuum process, and monitor the sealing progress.

4. Seal bar: Our machine has a sealing strip or bar that creates the airtight seal on the packaging. The size of the seal bar determines the maximum width of the bag or container that can be sealed.

5. Bag cutter: Our models may include a built-in bag cutter, allowing you to customize the size of the bags to fit your products precisely.

6. Built-in roll storage: Our table top vacuum sealers have integrated storage for vacuum sealing rolls, making it convenient to have the packaging material readily available.

7. Compact size: Our Table top vacuum packing machines are designed to be space-saving and easy to use in smaller kitchens or limited countertop areas.

8. Versatility: While primarily used for food preservation, these machines can also be used to vacuum seal non-food items, such as important documents or clothing for travel.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Powervac |

| Driven Type | Electric |

| Color | Silver |

| Condition | New |

| Automatic Grade | Semi Automatic |

| Model Number | TT-300 |

| Certification | ISO 9001:2008 |

| Voltage | 230 Volts |

| Packaging Type | Pouch |

| Type | Flour Packing Machine |

| Weight | 40 Kg |

| Function | Packing |

| Country of Origin | India |

| Sealing Length | 400mm |

| Chamber Type | Single |

| Product Code | TT-300 |

| Payment Terms | L/C, T/T, Western Union, Other |

| Delivery Time | 3 to 4 Weeks |

Preferred Buyer From

| Location | Worldwide |

Standard Features:

- Horizontal Table top showy design suitable for retail grocery shops, small dairy shops, super malls, etc.

- Transparent acrylic top to see packing process.

- Mitsubishi (Japan) Plc based control panel with 4-Line LCD Display, adjustable vacuum time, sealing time, etc.

- High speed vacuum pump (Busch Germany).

- Stainless steel body, no sharp edges, use cast aluminium & other nonferrous materials to safe rust issue and easy cleaning.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Powervac |

| Material | Stainless Steel |

| Driven Type | Electric |

| Color | Silver |

| Condition | New |

| Automatic Grade | Semi Automatic |

| Certification | ISO 9001:2008 |

| Voltage | 230 Volt |

| Packaging Type | Pouch |

| Model No. | TT-300 |

| Type | Vacuum Packaging Machine |

| Function | Sealing, Packing |

| Country of Origin | India |

| Weight | 40 Kg |

| Sealing Length | 400mm |

| Chamber Type | Single |

| Phase | Single Phase |

| Product Code | TT-300 |

| Payment Terms | L/C, T/T, Western Union, Other |

| Delivery Time | 3 to 4 Weeks |

Preferred Buyer From

| Location | Worldwide |

Standard Features:

· Horizontal Table top showy design suitable for retail grocery shops, small dairy shops, super malls, etc.

· Transparent acrylic top to see packing process.

· Mitsubishi (Japan) Plc based control panel with 4-Line LCD Display, adjustable vacuum time, sealing time, etc.

· High speed vacuum pump (Busch Germany).

· Stainless steel body, no sharp edges, use cast aluminium & other nonferrous materials to safe rust issue and easy cleaning.

Technical Specifications:

Machine Model: TT-300

Distance Between Seal Bars: 290

Usable Chamber Height: 85

Seal Bar Length: 300

No. of Seal Bar: 1

Seal Width: 6

| Business Type | Manufacturer, Exporter, Supplier |

| Capacity | 2 Cycles Per Minute |

| Brand Name | Powervac |

| Material | Stainless Steel |

| Driven Type | Electric |

| Color | Silver |

| Condition | New |

| Automatic Grade | Semi Automatic |

| Application | Vacuum Packing |

| Certification | ISO 9001:2008 |

| Voltage | 230 Volts, 50 Hz. I Phase/ III Phase - as per client |

| Type | Pouch Packaging Machine |

| Country of Origin | Made In India |

| Load Capacity | 100-150 Kg |

| Sealing Length | 600 mm |

| Model Name/Number | SCH 500 |

| Product Code | SCH 500 |

| Payment Terms | L/C, T/T, Western Union, Other |

| Delivery Time | 3 to 4 Weeks |

Preferred Buyer From

| Location | Worldwide |

Vacuum packing, also known as vacuum sealing, is a method of packaging that removes air from the package before sealing it. It involves the use of a vacuum sealer machine to create an airtight seal around the item or food being packaged.

The vacuum packing process typically involves the following steps:

1. Preparation: Ensure that the item or food you want to vacuum pack is clean and dry. This is important to prevent any moisture from affecting the sealing process or the product itself.

2. Place the item in a vacuum bag: Put the item you want to package inside a specially designed vacuum bag. These bags are usually made of durable, airtight materials such as polyethylene or nylon. Make sure to leave enough space at the opening of the bag for sealing.

3. Vacuum sealing: Place the open end of the bag into the vacuum sealer machine and close the lid. The machine will then remove the air from the bag, creating a vacuum. The exact process may vary depending on the type and model of the vacuum sealer you are using. Once the air is removed, the machine will automatically seal the bag.

4. Inspection: After sealing, visually inspect the package to ensure that it is properly sealed and airtight. Check for any leaks or gaps in the seal.

Vacuum packing offers several benefits, including:

1. Extended shelf life: By removing air from the package, vacuum packing helps to inhibit the growth of bacteria, molds, and other microorganisms. This can significantly extend the shelf life of perishable items, such as food.

2. Preservation of freshness: Vacuum packing helps preserve the quality, flavour, and texture of food by preventing exposure to oxygen, which can lead to oxidation and spoilage.

3. Protection from freezer burn: When storing food in the freezer, vacuum sealing helps to prevent freezer burn, which occurs when food comes into contact with air and becomes dehydrated.

4. Space-saving: Vacuum packing removes excess air, allowing items to be tightly packed and occupying less space. This can be particularly useful when packing for travel or maximizing storage space.

Vacuum packing is commonly used in various industries, including food packaging, electronics, pharmaceuticals, and household storage. It is an effective method for preserving and protecting a wide range of products.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Powervac |

| Material | Stainless Steel |

| Driven Type | Electric |

| Condition | New |

| Automatic Grade | Automatic,Semi Automatic |

| Certification | ISO 9001:2008 |

| Voltage | 230 Volts |

| Packaging Type | Pouch |

| Model No. | SCH-650,TT-300 |

| Type | Vacuum Packaging Machine |

| Function | Sealing, Packing |

| Country of Origin | India |

| Weight | 40 Kg |

| Sealing Length | 400mm |

| Phase | Single Phase |

| Chamber Type | Single |

| Product Code | SCH-650 |

| Payment Terms | L/C, T/T, Western Union, Other |

| Delivery Time | 3 to 4 Weeks |

Preferred Buyer From

| Location | Worldwide |

Our table top vacuum packing machine is a compact and convenient appliance used to remove air from packaging, such as bags or containers, in order to extend the shelf life of food and other perishable items. By removing air from the packaging, it helps prevent the growth of bacteria and molds, keeping the contents fresher for a longer period.

Key features of our table top vacuum packing machine typically include:

1. Vacuum sealing: Our Machine has motorized vacuum pump from (busch -Germany) to suck the air out of the packaging, creating an airtight seal around the contents.

2. Seal settings: Our machine allows you to adjust the seal time and intensity, which can be useful when working with different types of packaging materials or products.

3. Control panel: Our table top vacuum sealer has a user-friendly control panel from MITSUBHISHI –Japan that allows you to adjust settings, start/stop the vacuum process, and monitor the sealing progress.

4. Seal bar: Our machine has a sealing strip or bar that creates the airtight seal on the packaging. The size of the seal bar determines the maximum width of the bag or container that can be sealed.

5. Bag cutter: Our models may include a built-in bag cutter, allowing you to customize the size of the bags to fit your products precisely.

6. Built-in roll storage: Our table top vacuum sealers have integrated storage for vacuum sealing rolls, making it convenient to have the packaging material readily available.

7. Compact size: Our Table top vacuum packing machines are designed to be space-saving and easy to use in smaller kitchens or limited countertop areas.

8. Versatility: While primarily used for food preservation, these machines can also be used to vacuum seal non-food items, such as important documents or clothing for travel.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Powervac |

| Material | Stainless Steel |

| Driven Type | Electric |

| Condition | New |

| Automatic Grade | Automatic,Semi Automatic |

| Certification | ISO 9001:2008 |

| Voltage | 230 Volts,50 Hz. I Phase/ III Phase - As Per Client |

| Packaging Type | Pouch |

| Model No. | SCH-650 |

| Type | Vacuum Packaging Machine |

| Function | Sealing, Packing |

| Country of Origin | India |

| Weight | 250 Kg |

| Sealing Length | 620mm |

| Chamber Type | Single |

| Chamber Size | 500mm |

| Dimension | 1050(L) x 750(W) x 960(H)mm |

| Product Code | SCH-650 |

| Payment Terms | L/C, T/T, Western Union, Other |

| Delivery Time | 3 to 4 Weeks |

Preferred Buyer From

| Location | Worldwide |

Our table top vacuum packing machine is a compact and convenient appliance used to remove air from packaging, such as bags or containers, in order to extend the shelf life of food and other perishable items. By removing air from the packaging, it helps prevent the growth of bacteria and molds, keeping the contents fresher for a longer period.

Key features of our table top vacuum packing machine typically include:

1. Vacuum sealing: Our Machine has motorized vacuum pump from (busch -Germany) to suck the air out of the packaging, creating an airtight seal around the contents.

2. Seal settings: Our machine allows you to adjust the seal time and intensity, which can be useful when working with different types of packaging materials or products.

3. Control panel: Our table top vacuum sealer has a user-friendly control panel from MITSUBHISHI –Japan that allows you to adjust settings, start/stop the vacuum process, and monitor the sealing progress.

4. Seal bar: Our machine has a sealing strip or bar that creates the airtight seal on the packaging. The size of the seal bar determines the maximum width of the bag or container that can be sealed.

5. Bag cutter: Our models may include a built-in bag cutter, allowing you to customize the size of the bags to fit your products precisely.

6. Built-in roll storage: Our table top vacuum sealers have integrated storage for vacuum sealing rolls, making it convenient to have the packaging material readily available.

7. Compact size: Our Table top vacuum packing machines are designed to be space-saving and easy to use in smaller kitchens or limited countertop areas.

8. Versatility: While primarily used for food preservation, these machines can also be used to vacuum seal non-food items, such as important documents or clothing for travel.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Powervac |

| Material | Stainless Steel |

| Driven Type | Electric |

| Condition | New |

| Automatic Grade | Automatic |

| Certification | ISO 9001:2008 |

| Voltage | 230V |

| Packaging Type | Bags |

| Type | Vacuum Packaging Machine |

| Function | Sealing, Packing |

| Country of Origin | Made In India |

| Sealing Length | 450mm |

| Chamber Type | Chamber Less |

| Sealing Power | 750 W |

| Frequency | 60 Hz |

| Payment Terms | L/C, T/T, Western Union, Other |

| Delivery Time | 3 to 4 weeks |

Preferred Buyer From

| Location | Worldwide |

A nozzle-type chamberless vacuum packing machine is a type of packaging equipment used to remove air from packages or containers to extend the shelf life of food products or to protect other items from oxidation or spoilage. Unlike traditional chamber vacuum sealers that require a vacuum chamber, the nozzle-type chamberless machine uses a nozzle to remove air from the package directly.

Here's how a typical nozzle-type chamberless vacuum packing machine works:

1. Package Preparation: The item to be packed is placed in a specialized vacuum-sealing bag or container. The bag is typically made of a material that can withstand the vacuum sealing process and is compatible with the specific machine being used.

2. Sealing the Bag: The open end of the bag is placed under the sealing bar of the machine. The sealing bar applies heat to melt the bag and create an airtight seal.

3. Vacuuming: Once the bag is sealed, the machine activates the nozzle. The nozzle is inserted into a small opening in the bag, and a vacuum is created inside the bag by removing the air through the nozzle. This process can be achieved using a powerful suction mechanism or by displacing the air with an inert gas such as nitrogen.

4. Sealing the Nozzle Opening: After the air is removed, the nozzle is withdrawn, and the small opening where the nozzle was inserted is sealed. This ensures that the package remains airtight.

5. Completion: The vacuum-sealed package is now ready for storage, shipping, or display. The absence of air inside the package helps preserve the freshness and quality of the product, reduces the risk of spoilage, and can also prevent the growth of bacteria or molds.

Nozzle-type chamberless vacuum packing machines are commonly used in the food industry, particularly for packaging perishable items such as meat, fish, cheese, and vegetables. They can also be used for non-food applications, such as packaging electronic components, pharmaceuticals, and other sensitive items that require protection from moisture or air exposure.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Powervac |

| Material | LDPE |

| Driven Type | Electric |

| Condition | New |

| Automatic Grade | Automatic,Automatic |

| Certification | ISO 9001:2008 |

| Voltage | 440V |

| Packaging Type | Bakery, Confectionary, Dry Fruit, Ready Meals, Meet, Poultry, Cheese, Dairy, Produce, Sea Food, etc |

| Model No. | TMF-500,TMF-500D |

| Type | Vacuum Packaging Machine |

| Country of Origin | India |

| Capacity | 100 Kg/hr |

| Motor | Servo Motor |

| I Deal In | New Only |

Preferred Buyer From

| Location | Worldwide |

We are Providing Vacuum Thermoforming Machine for Food Packaging.

A vacuum thermoforming machine, also known as a foam molding machine or foam expansion machine, is a type of industrial equipment used to produce foam products through a process known as thermoforming and foam expansion. Thermoforming involves heating a plastic sheet until it becomes pliable, then shaping it over a mold and cooling it to create a specific product shape. Foam expansion, on the other hand, involves injecting gas or air into a polymer melt to create a foam structure within the material.

Thermofoaming machines combine these processes to create foam products, often used in various industries such as packaging, automotive, construction, and more. The foam products can offer benefits such as light weighting, thermal insulation, and cushioning.

Here's a general overview of how a thermofoaming machine works:

1. Material Preparation: The machine starts by feeding plastic pellets (usually thermoplastic materials) into a hopper. These pellets are then melted down to form a polymer melt.

2. Molding: The melted polymer is extruded onto a mold or a set of molds. The molds are designed to give the desired shape to the final foam product.

3. Foam Expansion: During the molding process, a gas or air is introduced into the polymer melt. This can be achieved by various methods, such as chemical blowing agents or physical foaming techniques. As the gas expands, it creates a cellular foam structure within the material.

4. Cooling and Solidification: Once the foam has expanded and taken on the desired shape, the material is cooled rapidly to solidify the foam structure.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Powervac |

| Material | Stainless Steel |

| Driven Type | Electric |

| Condition | New |

| Automatic Grade | Semi Automatic,Semi Automatic |

| Certification | ISO 9001:2008 |

| Voltage | 230 Volts |

| Packaging Type | Pouch |

| Model No. | TT-300 |

| Type | Vacuum Packaging Machine |

| Weight (Kg) | 40 Kg |

| Function | Sealing, Packing |

| Country of Origin | India |

| Chamber dimensions (L1xW1xH1) (mm) | 740(L) X 425(W) X 340(H)mm |

| Sealing Length | 400mm |

| Chamber Type | Single |

| Distance Between Seal Bars | 290 |

| No. of Seal Bar | 1 |

| Product Code | TT-300 |

| Port | 3 to 4 Weeks |

| Payment Terms | L/C, T/T, Western Union, Other |

Preferred Buyer From

| Location | Worldwide |

Standard Features:

- Horizontal Table top showy design suitable for retail grocery shops, small dairy shops, super malls, etc.

- Transparent acrylic top to see packing process.

- Mitsubishi (Japan) Plc based control panel with 4-Line LCD Display, adjustable vacuum time, sealing time, etc.

- High speed vacuum pump (Busch Germany).

- Stainless steel body, no sharp edges, use cast aluminium & other nonferrous materials to safe rust issue and easy cleaning.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Powervac |

| Material | Stainless Steel,Stainless Steel |

| Driven Type | Electric |

| Condition | New |

| Automatic Grade | Semi Automatic,Semi Automatic |

| Certification | ISO 9001:2008 |

| Packaging Type | Bags |

| Model No. | VNM-650 |

| Type | Vacuum Packaging Machine |

| Function | Sealing, Packing |

| Country of Origin | Made In India |

| Seal length L2 (mm) | 600mm |

| Sealing Length | 600mm |

| Gas Flushing | Yes |

| Product Code | VNM-650 |

| Payment Terms | L/C, T/T, Western Union, Other |

| Delivery Time | 3 to 4 Weeks |

Preferred Buyer From

| Location | Worldwide |

A nozzle-type chamberless vacuum packing machine is a type of packaging equipment used to remove air from packages or containers to extend the shelf life of food products or to protect other items from oxidation or spoilage. Unlike traditional chamber vacuum sealers that require a vacuum chamber, the nozzle-type chamberless machine uses a nozzle to remove air from the package directly.

Here's how a typical nozzle-type chamberless vacuum packing machine works:

1. Package Preparation: The item to be packed is placed in a specialized vacuum-sealing bag or container. The bag is typically made of a material that can withstand the vacuum sealing process and is compatible with the specific machine being used.

2. Sealing the Bag: The open end of the bag is placed under the sealing bar of the machine. The sealing bar applies heat to melt the bag and create an airtight seal.

3. Vacuuming: Once the bag is sealed, the machine activates the nozzle. The nozzle is inserted into a small opening in the bag, and a vacuum is created inside the bag by removing the air through the nozzle. This process can be achieved using a powerful suction mechanism or by displacing the air with an inert gas such as nitrogen.

4. Sealing the Nozzle Opening: After the air is removed, the nozzle is withdrawn, and the small opening where the nozzle was inserted is sealed. This ensures that the package remains airtight.

5. Completion: The vacuum-sealed package is now ready for storage, shipping, or display. The absence of air inside the package helps preserve the freshness and quality of the product, reduces the risk of spoilage, and can also prevent the growth of bacteria or molds.

Nozzle-type chamberless vacuum packing machines are commonly used in the food industry, particularly for packaging perishable items such as meat, fish, cheese, and vegetables. They can also be used for non-food applications, such as packaging electronic components, pharmaceuticals, and other sensitive items that require protection from moisture or air exposure.

| Business Type | Manufacturer, Exporter, Supplier |

| Sealing Length | 500mm |

| Phase | Single Phase |

| Chamber Type | Single |

| Automation Grade | Semi Automatic |

| Model Name/Number | SCV500 |

| Voltage | 230 Volts, 50 Hz. I Phase |

| Power | 1 Kw |

| Dimension | 760(L) x 730(W) x 1300(H) mm |

| Brand Name | Powervac |

Preferred Buyer From

| Location | Worldwide |

Here's how a typical vertical type vacuum packing machine works:

- Preparation: The operator places the item or product to be packaged into a specially designed plastic bag or pouch.

- Loading: The loaded bag is then placed in the vertical chamber of the machine, ensuring that the open end of the bag is positioned over the sealing bar.

- Vacuuming: The machine begins the vacuuming process. A vacuum pump removes the air from the chamber, creating a low-pressure environment. As a result, the air is also drawn out from the bag through the open end.

- Sealing: Once the desired level of vacuum is achieved, the sealing bar heats up and melts the open end of the bag. The melted plastic fuses together, creating an airtight seal.

- Cooling: After sealing, the machine cools down the sealed portion of the bag, solidifying the plastic and ensuring a secure closure.

- Unloading: The finished vacuum-sealed package can be removed from the machine, ready for storage, shipping, or retail display.