| Business Type | Manufacturer, Exporter, Supplier |

| Sealing Length | 400mm |

| Chamber Type | Single |

| Automation Grade | Semi Automatic |

| Model Name/Number | TT-300 |

| Country of Origin | Made in India |

| No. of Seal Bar | 1 |

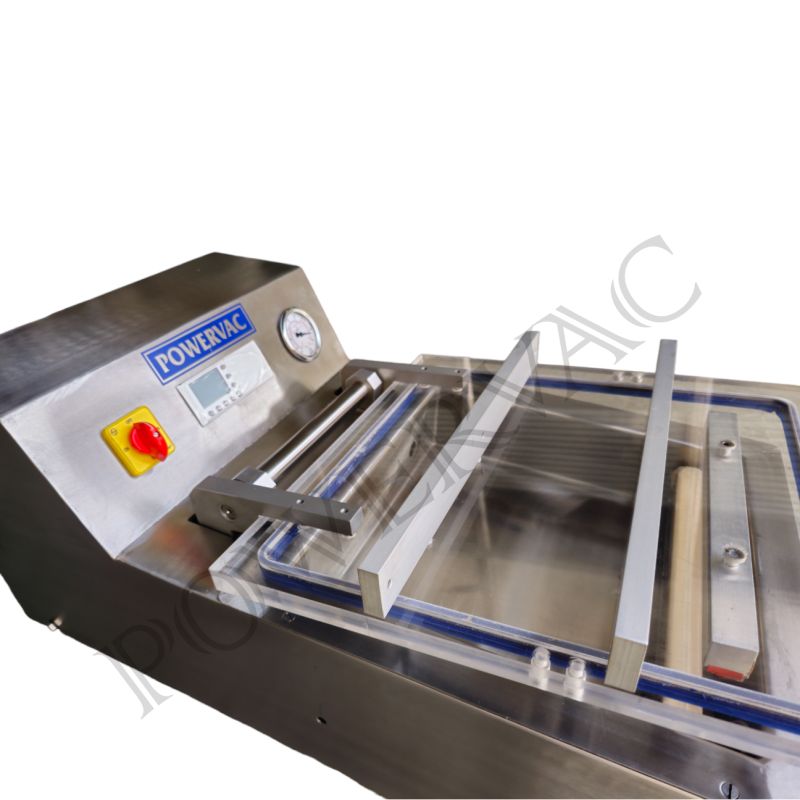

| Brand Name | Powervac |

Preferred Buyer From

| Location | Worldwide |

Standard Features:

- Horizontal Table top showy design suitable for retail grocery shops, small dairy shops, super malls, etc.

- Transparent acrylic top to see packing process.

- Mitsubishi (Japan) Plc based control panel with 4-Line LCD Display, adjustable vacuum time, sealing time, etc.

- High speed vacuum pump (Busch Germany).

- Stainless steel body, no sharp edges, use cast aluminium & other nonferrous materials to safe rust issue and easy cleaning.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Powervac |

| Driven Type | Electric |

| Automation Grade | Automatic |

| Voltage | 430V |

| Type | Single Chamber Vacuum Packager |

| Phase | Single Phase |

| Certfication | ISO 9001:2008 |

| Country of Origin | Made In India |

| Sealing Length | 620mm |

| Chamber Type | Single |

| Model Name/Number | SCV 650 |

| Frequency | 50 Hz |

| Sealing Power | 750 W |

| Material | Stainless Steel |

| Product Code | SCV-650 |

| Payment Terms | L/C, T/T, Western Union, Other |

| Delivery Time | 3 to 4 weeks |

Preferred Buyer From

| Location | Worldwide |

Here are some key features and components typically found in a vertical single chamber vacuum packing machine:

- Chamber: The machine consists of a single chamber where the product to be vacuum packed is placed. The chamber is enclosed by a transparent lid or door, allowing the operator to monitor the packaging process.

- Vacuum System: The vacuum system is responsible for removing air from the chamber and the packaging material. It usually consists of a vacuum pump that creates a vacuum environment inside the chamber.

- Sealing Mechanism: The machine has a sealing mechanism that creates an airtight seal on the packaging material. It may use heat sealing or other sealing methods depending on the type of packaging material used.

- Control Panel: A control panel is provided to operate and control the packaging process. It allows the operator to set parameters such as vacuum strength, sealing time, and other settings.

- Construction: These machines are usually made of stainless steel that are easy to clean and maintain. The construction should be sturdy to withstand the vacuum pressure and ensure reliable operation.

| Business Type | Manufacturer, Exporter, Supplier |

| Frequency | 50 Hz |

| Body Material | Stainless Steel |

| Phase | Single Phase |

| Brand Name | Powervac |

| Driven Type | Electric |

| Color | Grey |

| Condition | New |

| Automatic Grade | Automatic |

| Certification | ISO 9001:2008 |

| Voltage | 230 V |

| Packaging Type | Pouch |

| Country of Origin | Made In India |

| Sealing Length | 400mm |

| Chamber Type | Single |

| Bag Type | Vacuum Pouch |

| Sealing Power | 500 W, 750 W |

| Product Code | SCH-650 |

| Payment Terms | L/C, T/T, Western Union, Other |

| Delivery Time | 3 to 4 Weeks |

Preferred Buyer From

| Location | Worldwide |

Key features of our table top vacuum packing machine typically include:

- Vacuum sealing: Our Machine has motorized vacuum pump from (busch -Germany) to suck the air out of the packaging, creating an airtight seal around the contents.

- Seal settings: Our machine allows you to adjust the seal time and intensity, which can be useful when working with different types of packaging materials or products.

- Control panel: Our table top vacuum sealer has a user-friendly control panel from MITSUBHISHI –Japan that allows you to adjust settings, start/stop the vacuum process, and monitor the sealing progress.

- Seal bar: Our machine has a sealing strip or bar that creates the airtight seal on the packaging. The size of the seal bar determines the maximum width of the bag or container that can be sealed.

- Bag cutter: Our models may include a built-in bag cutter, allowing you to customize the size of the bags to fit your products precisely.

- Built-in roll storage: Our table top vacuum sealers have integrated storage for vacuum sealing rolls, making it convenient to have the packaging material readily available.

- Compact size: Our Table top vacuum packing machines are designed to be space-saving and easy to use in smaller kitchens or limited countertop areas.

- Versatility: While primarily used for food preservation, these machines can also be used to vacuum seal non-food items, such as important documents or clothing for travel.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Powervac |

| Material | Stainless Steel,Stainless Steel |

| Driven Type | Electric |

| Color | Silver |

| Condition | New |

| Automatic Grade | Semi Automatic,Semi Automatic |

| Certification | ISO 9001:2008 |

| Voltage | 230 Voltage |

| Packaging Type | Pouch |

| Model No. | TT-300 |

| Type | Vacuum Packaging Machine |

| Weight (Kg) | 40 kg |

| Function | Sealing, Packing |

| Country of Origin | India |

| Chamber dimensions (L1xW1xH1) (mm) | 740(L) x 425(W) x 340(H)mm |

| Sealing Length | 400mm |

| Chamber Type | Single |

Preferred Buyer From

| Location | Worldwide |

Standard Features:

- Horizontal Table top showy design suitable for retail grocery shops, small dairy shops, super malls, etc.

- Transparent acrylic top to see packing process.

- Mitsubishi (Japan) Plc based control panel with 4-Line LCD Display, adjustable vacuum time, sealing time, etc.

- High speed vacuum pump (Busch Germany).

- Stainless steel body, no sharp edges, use cast aluminium & other nonferrous materials to safe rust issue and easy cleaning.

| Business Type | Manufacturer, Exporter, Supplier |

| Sealing Length | 400mm |

| Chamber Type | Double |

| Automation Grade | Semi-Automatic |

| Voltage | 430V |

| Sealing Power | 350 W |

| Driven Type | Vertical |

| Frequency | 50 Hz |

| Phase | 3 Phase |

| Body Material | Stainless Steel |

| Country of Origin | Made in India |

| Brand Name | Powervac |

Preferred Buyer From

| Location | Worldwide |

Here's how a double chamber vacuum packing machine generally works:

- Placement of Products: The operator places the products to be packaged in the designated area of one chamber. These products can be food items, perishable goods, industrial components, or any other items that require a vacuum-sealed packaging.

- Sealing the Chamber: Once the products are placed in the chamber, the operator closes the chamber door securely, ensuring an airtight seal.

- Evacuation of Air: The vacuum packing machine starts the packaging process by removing air from the chamber. It creates a low-pressure environment within the chamber by using a vacuum pump or a venturi system. The pump removes air from the chamber, creating a vacuum.

- Sealing the Package: Once the desired level of vacuum is achieved, the machine seals the package. It uses a heat-sealing mechanism to close and seal the packaging material (such as plastic bags or pouches) around the products. The heat sealing ensures an airtight seal, preventing air from re-entering the package.

- Transfer to Second Chamber: While one chamber is sealing and packaging, the operator can load the second chamber with products to be packaged. This allows for continuous packaging operations, maximizing efficiency.

- Releasing Vacuum and Opening Chamber: Once the sealing process is complete, the vacuum inside the chamber is released, and the chamber door is opened. The packaged products can be removed, and the chamber is ready for the next cycle.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Powervac |

| Material | Stainless Steel |

| Driven Type | Electric |

| Color | Silver |

| Condition | New |

| Automatic Grade | Semi Automatic,Semi Automatic |

| Power | 230 Volts, 50 Hz. I Phase |

| Certification | ISO 9001:2008 |

| Voltage | 230 Volts |

| Packaging Type | Pouch |

| Type | Vacuum Packaging Machine |

| Weight (Kg) | 250 KG |

| Function | Sealing, Packing |

| Country of Origin | India |

| Weight | 300 Kg |

| Sealing Length | 500mm |

| Chamber Type | Single |

| Chamber Size | 540 x 450 mm |

| Product Code | SCV-500 |

| Payment Terms | L/C, T/T, Western Union, Other |

| Delivery Time | 3 to 4 Weeks |

Preferred Buyer From

| Location | Worldwide |

A vertical type brick vacuum packing machine, is a packaging equipment used to package products in a brick-shaped format while removing air (vacuum) from the package.

Here's a breakdown of the key components and the working process of a typical vertical type brick vacuum packing machine:

1. Product Feeding: The machine is equipped with a feeding system that allows the product to be loaded into the packaging machine. The product can be in the form of granules, powders, liquids, or solid pieces, depending on the machine's capabilities.

2. Film Unwinding: The packaging material, usually a flexible film roll, is unwound and guided through the machine. The film can be made of various materials, such as plastic, aluminium, or laminates, depending on the product's requirements and the desired level of vacuum sealing.

3. Forming the Package: The film is formed into a tube by vertical sealing jaws. The sealing jaws create vertical seals on both sides of the film, forming a continuous tube to hold the product.

4. Product Filling: The product is dispensed into the formed tube of the packaging material.

5. Vacuum Sealing: Once the product is filled, the machine starts the vacuum sealing process. The open end of the tube is fed into a vacuum chamber, where the air is extracted, creating a vacuum inside the package. The vacuum helps to extend the product's shelf life by reducing oxygen levels, preventing spoilage, and maintaining product freshness.

6. Sealing and Cutting: After the vacuum is created, the machine seals the open end of the tube, creating a sealed brick-shaped package.

Vertical type brick vacuum packing machines are commonly used in the food industry for packaging products like coffee, snacks, cereals, frozen foods, and more. They offer efficient and hygienic packaging solutions with the added benefit of vacuum sealing to enhance product quality and shelf life.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Powervac |

| Material | Stainless Steel |

| Driven Type | Electric |

| Color | Silver |

| Condition | New |

| Automatic Grade | Semi Automatic,Semi Automatic |

| Certification | ISO 9001:2008 |

| Voltage | 230 Volts,50 Hz. I Phase |

| Packaging Type | Pouch, Vacuum Packing |

| Model No. | SCV-500 |

| Type | Vacuum Packaging Machine |

| Function | Sealing, Packing |

| Country of Origin | India |

| Weight | 300 Kg |

| Sealing Length | 500mm |

| Chamber Type | Single |

| Chamber Size | 550mm |

| Bag Volume | Up to 15 Kg |

| Dimension | 760(L) x 730(W) x 1300(H) mm |

| Sealing Power | 500 W |

| Product Code | SCV-500 |

| Payment Terms | L/C, T/T, Western Union, Other |

| Delivery Time | 3 to 4 Weeks |

Preferred Buyer From

| Location | Worldwide |

A vertical type brick vacuum packing machine, is a packaging equipment used to package products in a brick-shaped format while removing air (vacuum) from the package.

Here's a breakdown of the key components and the working process of a typical vertical type brick vacuum packing machine:

1. Product Feeding: The machine is equipped with a feeding system that allows the product to be loaded into the packaging machine. The product can be in the form of granules, powders, liquids, or solid pieces, depending on the machine's capabilities.

2. Film Unwinding: The packaging material, usually a flexible film roll, is unwound and guided through the machine. The film can be made of various materials, such as plastic, aluminium, or laminates, depending on the product's requirements and the desired level of vacuum sealing.

3. Forming the Package: The film is formed into a tube by vertical sealing jaws. The sealing jaws create vertical seals on both sides of the film, forming a continuous tube to hold the product.

4. Product Filling: The product is dispensed into the formed tube of the packaging material.

5. Vacuum Sealing: Once the product is filled, the machine starts the vacuum sealing process. The open end of the tube is fed into a vacuum chamber, where the air is extracted, creating a vacuum inside the package. The vacuum helps to extend the product's shelf life by reducing oxygen levels, preventing spoilage, and maintaining product freshness.

6. Sealing and Cutting: After the vacuum is created, the machine seals the open end of the tube, creating a sealed brick-shaped package.

Vertical type brick vacuum packing machines are commonly used in the food industry for packaging products like coffee, snacks, cereals, frozen foods, and more. They offer efficient and hygienic packaging solutions with the added benefit of vacuum sealing to enhance product quality and shelf life.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | Powervac |

| Material | Stainless Steel |

| Driven Type | Electric |

| Condition | New |

| Automatic Grade | Automatic,Automatic |

| Certification | ISO 9001:2008 |

| Voltage | 430V |

| Packaging Type | Bags |

| Model No. | VM-800 |

| Type | Vertical |

| Function | Sealing, Packing |

| Country of Origin | India |

| Sealing Length | 620mm |

| Chamber Type | Single |

| Sealing Power | 500 W |

| Frequency | 50 Hz |

| Phase | 3 Phase |

| Product Code | VM-800 |

| Payment Terms | L/C, T/T, Western Union, Other |

| Delivery Time | 3 to 4 weeks |

Preferred Buyer From

| Location | Worldwide |

A vertical type vacuum packing machine is a specialized equipment used for vacuum packaging products in various industries such as food processing, pharmaceuticals, electronics, and more. This type of machine is designed to package products vertically, which can be beneficial for certain types of products or production lines.

The main purpose of a vacuum packing machine is to remove air from the packaging material, creating a vacuum environment inside the package. This process helps in extending the shelf life of products, preserving their freshness, and protecting them from external factors such as moisture, oxidation, and bacterial growth.

Here are some key features and functions typically found in a vertical type vacuum packing machine:

- Vertical Design: Unlike horizontal vacuum packing machines, which package products in a horizontal position, the vertical type machine packages products in a standing position. This design is suitable for packaging long or tall products that may not fit in a horizontal configuration.

- Vacuum Sealing: The machine uses a vacuum pump to remove air from the packaging material, creating a vacuum environment inside the package. This process helps to inhibit the growth of spoilage-causing microorganisms and preserve the quality of the product.

- Sealing Mechanism: Once the air is removed, the packaging material is sealed to maintain the vacuum environment. This can be done using heat sealing, where the packaging material is heated to create a secure seal.

- Control System: A control panel or interface allows operators to set and adjust parameters such as vacuum strength, sealing time, temperature, and other relevant settings. This helps in achieving the desired packaging results for different products.

- Packaging Material Compatibility: Vertical type vacuum packing machines can work with a variety of packaging materials such as flexible plastic films, laminates, and pouches. The specific material used depends on the product being packaged and its specific requirements.

- Optional Features: Depending on the specific machine model and manufacturer, there may be additional features available, such as gas flushing capabilities (to replace the vacuum with a modified atmosphere), adjustable vacuum levels, multiple sealing stations for higher production rates, conveyor systems for automated feeding, and more.