Kathwada, Ahmedabad, Gujarat

- GST NO. : 24BAKPP1655H1ZM

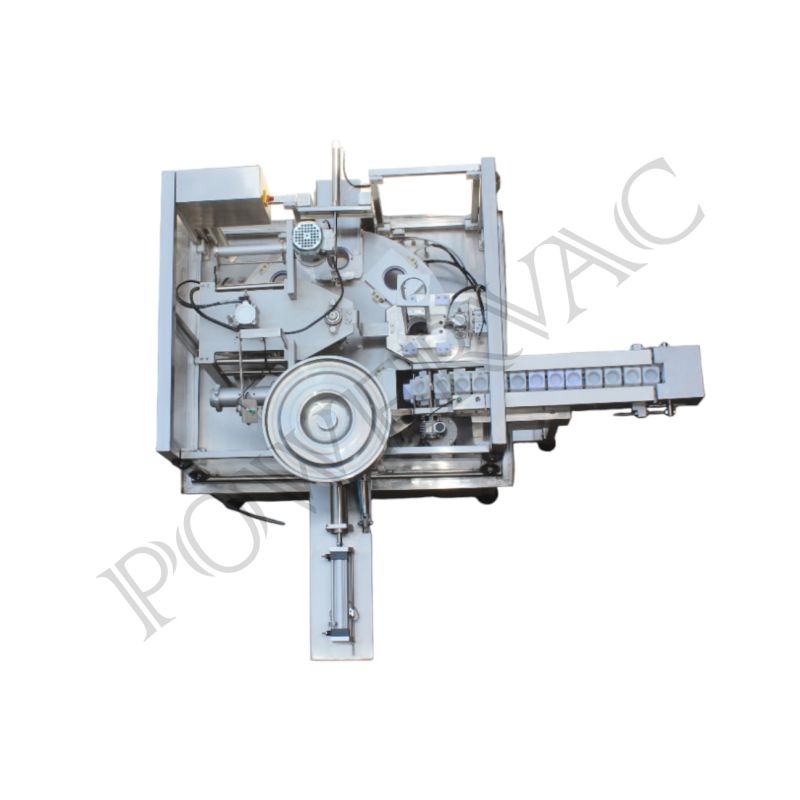

Cup Sealing Machine

Leading Manufacturers, Exporters, Wholesaler and Retailer of Automatic Cup Sealing Machine, Automatic Rotary Cup Filling and Sealing Machine, Lassi Cup Sealing Machine, Semi Automatic Cup Sealing Machine and Table Top Cup Sealing Machine from Ahmedabad.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Powervac |

| Material | Polypropylene |

| Color | Silver |

| Automatic Grade | Automatic |

| Certification | ISO 9001:2008 Certified |

| Voltage | 220V |

| Type | Automatic Cap Sealing Machine |

| Country of Origin | Made In India |

| Seal Machine Type | Cup Seal Machine |

| Cup Material | Polypropylene |

| Capacity per Hr | 1000 Cups per Hr |

| Product Code | Cup Sealing Machine |

| Payment Terms | L/C, T/T, Western Union, Other |

| Delivery Time | 3 to 4 Weeks |

Preferred Buyer From

| Location | Worldwide |

At Powervac we take pride in revolutionizing the packaging industry with our cutting-edge solutions. As a leading manufacturer, we specialize in the production of state-of-the-art vacuum packing machines, MAP (Modified Atmosphere Packaging) machines, tray sealers, and thermoforming machines.

**Our Expertise: **

**1. Vacuum Packing Machines: ** Our advanced vacuum packing machines are designed to preserve the freshness and extend the shelf life of a wide range of products. Whether you're packaging food items, electronics, or industrial components, our machines ensure optimal protection and longevity.

**2. MAP Machines: ** Our Modified Atmosphere Packaging machines enable precise control over the atmosphere inside the packaging, preserving the quality and freshness of perishable goods. We offer innovative solutions tailored to your specific product requirements.

**3. Tray Sealers: ** Our tray sealing technology ensures secure and hygienic packaging for various products. From ready-to-eat meals to delicate electronics, our tray sealers maintain product integrity and provide tamper-evident packaging solutions.

**4. Thermoforming Machines: ** Our thermoforming machines create customized packaging solutions by molding plastic into precise shapes, perfectly accommodating your products. These machines are ideal for items of diverse shapes and sizes, providing a professional and visually appealing packaging solution.

**Why Choose Us:**

- **Innovation: ** We stay at the forefront of technology, continuously innovating our machines to meet evolving market demands.

- **Quality Assurance: ** Our machines undergo rigorous quality checks to ensure reliability, durability, and consistent performance.

- **Custom Solutions: ** We understand that every product is unique. Our team works closely with clients to provide customized packaging solutions tailored to their specific needs.

- **Expert Support: ** With our experienced team of engineers and support staff, we offer unparalleled customer service, ensuring your operations run smoothly.

Partner with Powervac for packaging solutions that enhance the appeal, freshness, and safety of your products. Experience the difference that precision engineering and unwavering dedication to quality can make for your business.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Powervac |

| Driven Type | Electric |

| Condition | New |

| Automatic Grade | Automatic |

| Certification | Iso 9001:2008 |

| Voltage | 440V-3PH/50Hz |

| Type | Rotary Cup Filling Machine |

| Country of Origin | Made In India |

| Application | Cup Filling & Sealing |

| Filling Material | Liquid |

| Frequency | 50 Hz |

| Capacity per Hr | 800 Cups per Hr |

| Product Code | RCS-500 |

| Payment Terms | L/C, T/T, Western Union, Other |

| Delivery Time | 3 to 4 Weeks |

Preferred Buyer From

| Location | Worldwide |

Rotary packing machines are commonly used in the food industry to automate the process of packaging various products. These machines are designed to efficiently fill and seal products into containers in a continuous rotary motion. The packaging process typically involves the following steps:

I. Product Feeding: The Product would need to be fed into the machine's feeding system.

II. Filling: The Machine would have the filling mechanism that accurately Dispenses the Desired Quantity of product into each package.

III. Sealing: Once the products are filled into the packaging material, the machine would proceed to seal the packages. The sealing method would-be heat-sealing method depending on the packaging material used.

IV. Cutting and Separation: The continuous rotary motion of the machine would then move the sealed packages to a cutting and separation stage where individual packages are separated from the continuous packaging material.

V. Discharge: The sealed and separated packages would then be discharged from the machine, ready for further handling and distribution.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Powervac |

| Driven Type | Electric |

| Color | Silver |

| Condition | New |

| Automatic Grade | Automatic |

| Certification | ISO 9001:2008 Certified |

| Voltage | 220V |

| Country of Origin | Made In India |

| Capacity | 100-1000 Cups/Hrs |

| Usage | Cup Sealing |

| Filling Material | Liquid |

| Power Consumption | 1.5 Kw |

| Material | Stainless Steel |

Preferred Buyer From

| Location | Worldwide |

Here are some key features and benefits of tray sealing machines:

- Efficiency: Tray sealers offer high-speed sealing capabilities, allowing for faster production rates and increased efficiency.

- Product freshness and shelf life: The airtight seal created by the machine helps to preserve the freshness and extend the shelf life of the packaged products.

- Product presentation: Tray sealing machines provide a professional and visually appealing packaging solution, enhancing the product's presentation on store shelves.

- Customization options: The machines can be customized to accommodate different tray sizes and shapes, offering flexibility in packaging various products.

- Tamper-evident packaging: The sealed trays provide tamper-evident packaging, ensuring the integrity of the product and increasing consumer confidence.

- Hygiene and cleanliness: Tray sealing machines are designed to meet strict hygiene standards, with easy-to-clean surfaces and materials that are suitable for use in food processing environments.

- Reduced packaging waste: By using pre-cut films or rolls of film, tray sealing machines minimize packaging waste compared to other packaging methods.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Powervac |

| Material | Polypropylene |

| Driven Type | Electric |

| Color | Silver |

| Condition | New |

| Automatic Grade | Semi Automatic |

| Usage | Cup Sealing |

| Certification | ISO 9001:2008 Certified |

| Voltage | 240V |

| Capacity (Pouch Per Hour) | 700 Cups per hr |

| Type | Cup Sealing Machine |

| Frequency | 60 Hz |

| Country of Origin | Made In India |

| Seal Machine Type | Cup Seal Machine |

| Cup Material | Polypropylene |

| Capacity per Hr | 700 Cups per Hr |

| Payment Terms | L/C, T/T, Western Union, Other |

| Delivery Time | 3 to 4 Weeks |

Preferred Buyer From

| Location | Worldwide |

A semi-automatic cup sealing machine is a type of packaging equipment used to seal cups or containers with a r film. It is commonly used in the food , beverage, Sweet ,Namkeen , Meat products industry to seal filled cups

Unlike fully automatic machines, semi-automatic cup sealing machines require some manual operation from the user. Here's a general overview of how a typical semi-automatic cup sealing machine works:

1. Preparation: The cups or containers to be sealed are manually filled with the desired product. The cups are then placed on the machine's platform or tray.

2. Sealing Process: the cup is positioned under the sealing mechanism. The sealing mechanism can vary depending on the specific machine, but it typically involves applying heat to seal the film onto the cup. This can be done through methods such as heat sealing, induction sealing, or pressure sealing.

3. Sealing Operation: The user initiates the sealing process by pressing a button. The sealing mechanism then engages and seals the film onto the cup. The machine has a timer or sensor to control the sealing time or temperature, depending on the sealing method used.

4. Removal of Sealed Cups: After the sealing operation is complete, the user removes the sealed cups from the machine and places them on a tray or in a packaging container for further processing or distribution.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Powervac |

| Driven Type | Electric |

| Color | Silver |

| Condition | New |

| Automatic Grade | Automatic,Semi Automatic |

| Certification | ISO 9001:2008 Certified |

| Voltage | 220V |

| Specialities | Robust, Simple Operation |

| Type | Cup and Tray Sealing Machine |

| Frequency | 50/60 Hz |

| Phase | Three Phase |

| Country of Origin | India |

| Model | SGTS-500,SGTS-500 |

| Seal Machine Type | Cup Seal Machine |

| Capacity | 2-4 Cycles per Minute |

| Product Code | SGTS-500 |

| Payment Terms | L/C, T/T, Western Union, Other |

| Delivery Time | 3 to 4 Weeks |

Preferred Buyer From

| Location | Worldwide |

1. Gas Flushing: After the vacuum sealing process, the machine can introduce a specific gas or gas mixture into the tray or container. This is commonly done to replace the removed air with a modified atmosphere that helps further extend the product's shelf life. The gas used is typically a mixture of nitrogen, carbon dioxide, and/or oxygen, depending on the specific requirements of the product being packaged.

2. Sealing: Once the vacuum and gas flushing steps are completed, the machine applies heat to seal the tray or container. This ensures that the package remains airtight and prevents any leakage or contamination.

3. Cutting: Some machines also have cutting capabilities, allowing them to trim excess packaging material or create easy-open features on the sealed tray or container. This feature enhances the convenience and usability of the final product.

Overall, a vacuum tray sealing machine with gas flushing, sealing, and cutting functions is a versatile packaging solution commonly used in the food industry for products such as fresh meat, seafood, cheese, bakery items, and prepared meals. It helps maintain product quality, extend shelf life, and enhance food safety.